In the ever-evolving landscape of technology and construction, the interplay between innovation and materials has become increasingly significant. As we look toward 2025, emerging tech trends promise to reshape industries, and within this transformation lies a pivotal component: galvanized pipe. Known for its durability and corrosion resistance, galvanized pipe has not only proven its worth in traditional applications but is also adapting to new market demands driven by sustainability and efficiency. This blog explores the potential advantages of galvanized pipe in global markets, highlighting its role in modern construction projects and its integration with cutting-edge technologies. By examining trends forecasted for 2025, we aim to provide insights into how galvanized pipe will continue to be an essential material for builders and engineers striving for excellence in their designs. Join us as we delve into examples that illustrate the advantages of this versatile product in a rapidly changing world.

As we look towards the technological landscape of 2025, several key trends are emerging that are set to shape industries and influence the future of work. According to a recent Gartner report, three major challenges for executives will include the evolving demand for talent, shifts in managerial roles, and emerging risks associated with new talent pools. As organizations navigate these changes, the integration of AI and advanced technologies will become paramount, enabling businesses to foster innovation and adaptability in an increasingly dynamic environment.

One of the most significant trends in 2025 will be the expansion of smart energy solutions, particularly in the realm of photovoltaic systems. The drive towards renewable energy is not just a global imperative but a strategic opportunity for businesses. As noted in the energy sector's outlook, companies that strategically leverage AI in their solar technologies are poised to become leaders in this transformative field. Reports indicate that solar energy capacity is expected to double by 2025, underscoring the necessity for innovations that not only enhance efficiency but also reduce costs across the supply chain.

Moreover, the convergence of various technologies will lead to the establishment of smart ecosystems that integrate AI, IoT, and renewable energy sources. This holistic approach will facilitate the development of intelligent systems that not only optimize energy consumption but also contribute to sustainability goals. As governments and organizations invest in these technologies, the potential for enhancing productivity and fostering a greener future becomes an exciting reality, paving the way for what is often referred to as the Fourth Industrial Revolution.

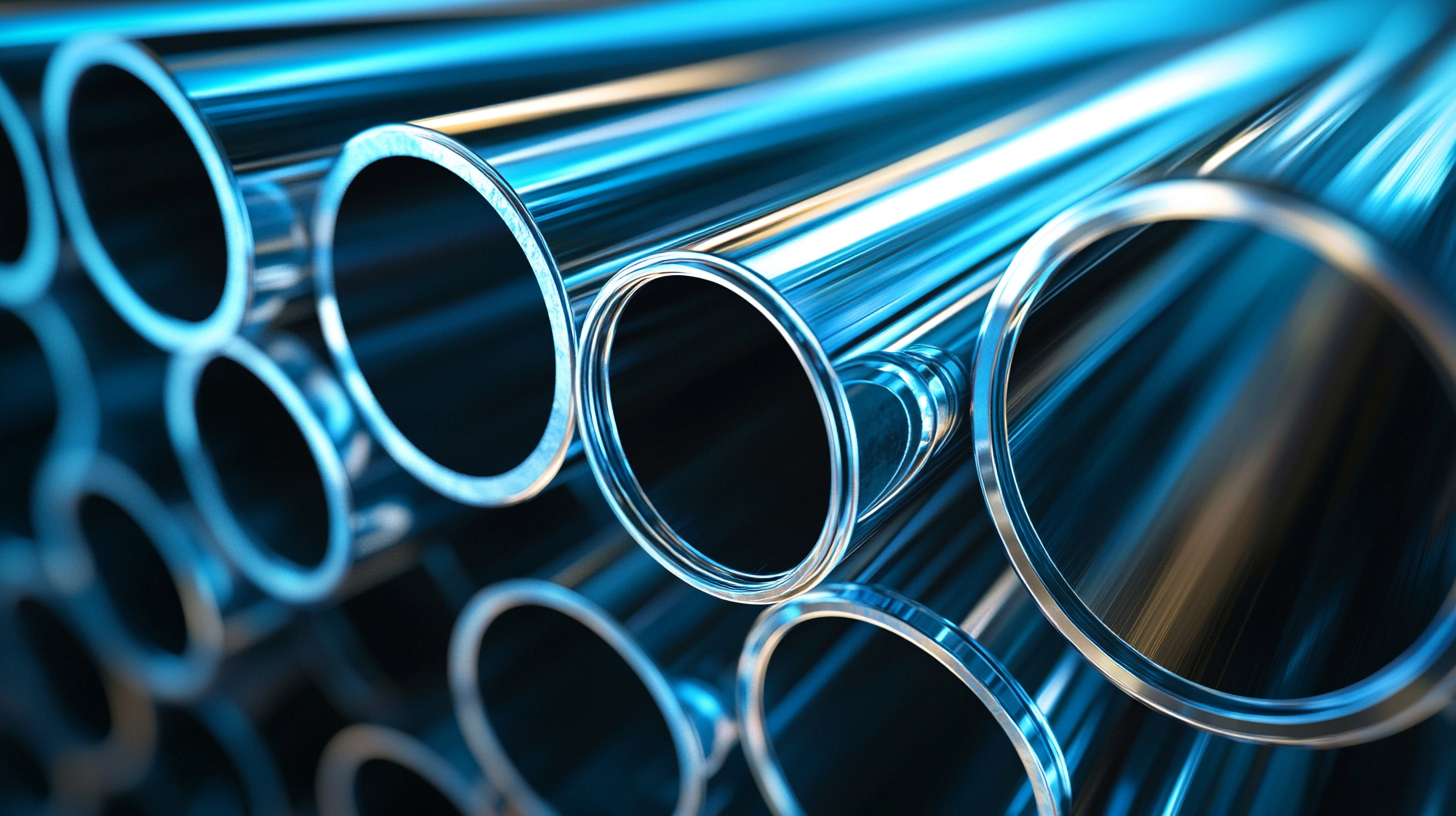

In the realm of modern infrastructure, galvanized pipes play a pivotal role due to their durability and corrosion resistance. These pipes, coated with a layer of zinc, provide a reliable solution for transporting water and other fluids. Their sturdy construction makes them ideal for both residential and commercial applications, contributing to the longevity of plumbing systems. As cities around the world continue to expand, the demand for galvanized pipes is soaring, driven by a need for robust infrastructure that can withstand environmental stresses and daily usage.

The global market for galvanized pipes is poised for significant growth by 2025, influenced by innovative construction techniques and an increasing emphasis on sustainability. As regions invest in upgrading aging infrastructure, the advantages of galvanized pipes—such as their low maintenance costs and recyclability—become increasingly appealing. Furthermore, with advancements in welding and joining methods, galvanized pipes are becoming even more versatile, paving the way for their use in a variety of modern construction projects. This trend not only reflects the ongoing evolution of our infrastructure but also highlights the importance of choosing materials that align with future-facing technological advancements.

The galvanized pipe industry is witnessing significant advancements, driven by top manufacturing facilities globally. These facilities employ cutting-edge technology and innovative practices to enhance pipe durability and performance, meeting the evolving demands of construction and infrastructure projects. Many leading manufacturers focus on sustainable production processes, reducing waste and energy consumption while maintaining high-quality standards. This shift not only benefits the environment but also positions these companies as frontrunners in a competitive market.

Among the key players in the industry, companies renowned for their state-of-the-art facilities are pioneering new techniques in galvanization, ensuring superior corrosion resistance and longevity of their products. As a result, galvanized pipes from these manufacturers are becoming increasingly sought after in various applications, from plumbing to structural supports. With a commitment to quality and a forward-thinking approach to technology, these manufacturing giants are setting benchmarks that drive the global galvanized pipe market towards a future of enhanced reliability and performance.

In the ever-evolving landscape of construction and infrastructure, galvanized pipes stand out as a formidable option due to their competitive advantages. Notably, their durability is a key factor that continues to captivate industries worldwide. Galvanized pipes are coated with a layer of zinc, which protects them from corrosion and rust, making them an excellent choice for both residential and commercial applications. This longevity not only results in lower maintenance costs over time but also significantly extends the lifespan of piping systems, reinforcing their status as a trusted material in the market.

Cost-effectiveness is another compelling reason for the growing preference for galvanized pipes. While the initial investment may be competitive, the reduced need for replacements and repairs ultimately translates to substantial savings. Additionally, as the global economy leans towards sustainability, galvanized pipes align well with these values. Their recyclability enhances their appeal in environmentally conscious projects, helping businesses meet increasingly stringent environmental regulations while promoting sustainable practices in construction. Embracing galvanized pipes today positions companies not only for immediate benefits but also for a more sustainable future.

| Dimension | Feature | Advantage |

|---|---|---|

| Durability | Corrosion Resistance | Longer lifespan, reduced maintenance |

| Cost-Effectiveness | Material and Installation | Lower overall expenses for projects |

| Sustainability | Recyclability | Minimized environmental impact |

| Strength | High Tensile Strength | Superior load-bearing capabilities |

| Versatility | Adaptable Applications | Used in various industries from construction to agriculture |

As we move toward 2025, the global market for galvanized pipes is set to witness significant transformations driven by various economic factors. According to a report by Market Research Future, the galvanized pipe market is projected to grow at a CAGR of 4.5%, reaching an estimated value of $4.2 billion by 2025. This growth is primarily fueled by the increasing demand in construction, oil and gas industries, and infrastructure developments, particularly in emerging economies.

However, challenges exist alongside these promising opportunities. Trade tariffs and environmental regulations are creating a complex landscape for exporters of galvanized pipes. The International Trade Administration highlights that countries imposing tariffs on imported steel products can disrupt existing trade relationships and impact pricing strategies. Furthermore, the transition toward greener technologies is pressuring manufacturers to innovate their production processes, as stricter policies on carbon emissions and sustainability become prevalent. Companies that can adapt to these changes while maintaining quality standards are likely to thrive in the competitive global market.