In the ever-evolving landscape of industrial applications, Metal Coils are critical components. They serve various sectors, including automotive, construction, and appliances. A recent market study indicates that the demand for metal coils is projected to grow at a CAGR of 4.5% through 2026. This growth highlights the importance of understanding the types and specifications of metal coils available today.

Industries increasingly rely on high-performance metal coils. They enhance efficiency and reduce costs. For instance, galvanized steel coils are well-regarded in the automotive sector for their durability. Reports suggest that nearly 60% of manufacturers prioritize corrosion resistance when selecting metal coils. Choosing the wrong type can lead to failures and increased expenses.

Yet, not all metal coils are created equal. Quality inconsistency can pose challenges. Some suppliers may compromise on manufacturing standards, affecting product reliability. As demand rises, industries must remain vigilant about their sources. Understanding metal coils and their applications becomes essential for strategic decision-making. This is especially true as companies venture into new project territories.

When considering metals for industrial coils, several key characteristics are vital. Metals used in coils must exhibit excellent conductivity, particularly for electrical applications. Copper and aluminum are the most common choices. According to the International Copper Association, copper’s electrical conductivity can reach up to 97%. This property enables efficient energy transfer in many industrial settings.

Durability is another critical factor. Many metals are notoriously prone to corrosion. For example, steel coils often require protective coatings to enhance lifespan. Reports indicate that stainless steel can withstand harsh environments better than regular steel. However, using stainless steel may raise material costs significantly, necessitating careful budget assessments.

Furthermore, the weight of the metal affects transportation and installation. Lighter materials are cheaper to transport, yet they may compromise strength. A balance must be struck between weight and durability. Some alloys offer improved strength without excessive weight, although they can be more challenging to source. These complexities highlight the importance of thorough evaluation before selecting materials for specific coil applications.

This chart illustrates the number of industrial applications for various types of metal coils used in 2026. Aluminum and copper show significant usage, while titanium has a more niche application base.

When it comes to metal coils, understanding the common types used in industrial applications is crucial. Various materials serve specific purposes. Steel coils, for instance, are widely employed in construction and manufacturing. They provide strength and durability. Aluminum coils are lighter and resist corrosion. This makes them ideal for transportation and packaging industries.

Copper coils, known for excellent conductivity, are essential in electrical applications. They are often used in HVAC systems. Another type is stainless steel coils, valued for their resistance to rust and staining. They find uses in food processing and medical environments. Each metal coil type has its strengths and weaknesses. However, not every choice fits all situations.

It is important to consider factors like cost, availability, and specific application needs. Some companies may overlook these details. They might go for a cheaper option without assessing long-term performance. This can lead to unexpected failures. The process of selecting the right metal coil requires thoughtful evaluation and understanding of industry requirements. It's a step often glossed over in the rush to production.

When selecting metal coils for industrial applications, numerous factors come into play. One key aspect is the material type. Common choices include stainless steel, aluminum, and carbon steel. Each material has a unique set of properties affecting its suitability for different tasks. For example, stainless steel offers excellent corrosion resistance, while aluminum is lighter and more malleable.

Another important factor is the thickness and width of the coils. These dimensions significantly impact the coil's performance. Thinner coils are easier to handle, but they may lack strength. Conversely, thicker coils provide sturdiness but can be more challenging to work with. It’s essential to balance these factors according to specific project requirements.

**Tips:** Always consult with a professional to ensure the right choice. Consider future needs too. Assessing potential wear and tear is crucial to avoid issues later. Understanding your industry’s standards can also guide your selection process. Ultimately, reflect on your decisions; the right coil leads to efficiency and lower costs. Don’t rush; take the time to weigh your options carefully.

| Material Type | Thickness (mm) | Width (mm) | Length (m) | Weight (kg) | Application |

|---|---|---|---|---|---|

| Stainless Steel | 2.0 | 1200 | 5.0 | 48.0 | Food Processing |

| Aluminum | 1.5 | 1500 | 3.0 | 36.0 | Automotive |

| Carbon Steel | 3.0 | 1000 | 4.0 | 59.0 | Construction |

| Galvanized Steel | 2.5 | 1200 | 6.0 | 72.0 | Fabrication |

| Copper | 0.8 | 800 | 2.0 | 20.0 | Electrical Wiring |

The metal coil industry is evolving rapidly. In 2026, advancements will focus on increased durability and flexibility. Manufacturers are exploring new alloys. These materials promise greater strength while remaining lightweight. Improved resistance to corrosion is paramount. This will ensure longevity in harsh environments.

Innovations in technology are reshaping production processes. Automation is driving efficiency. However, reliance on machines raises concerns about job displacement. Balancing tech and workforce is essential. Sustainability is another key factor. Eco-friendly methods are gaining traction. Using recycled materials is crucial for reducing waste.

The future looks promising, yet challenges remain. As technology evolves, companies must adapt. There is a need for constant research and development. The path forward is not without bumps. Engaging with industry experts will help navigate uncertainties. Collaboration may yield unexpected solutions. Embracing change could unlock new opportunities.

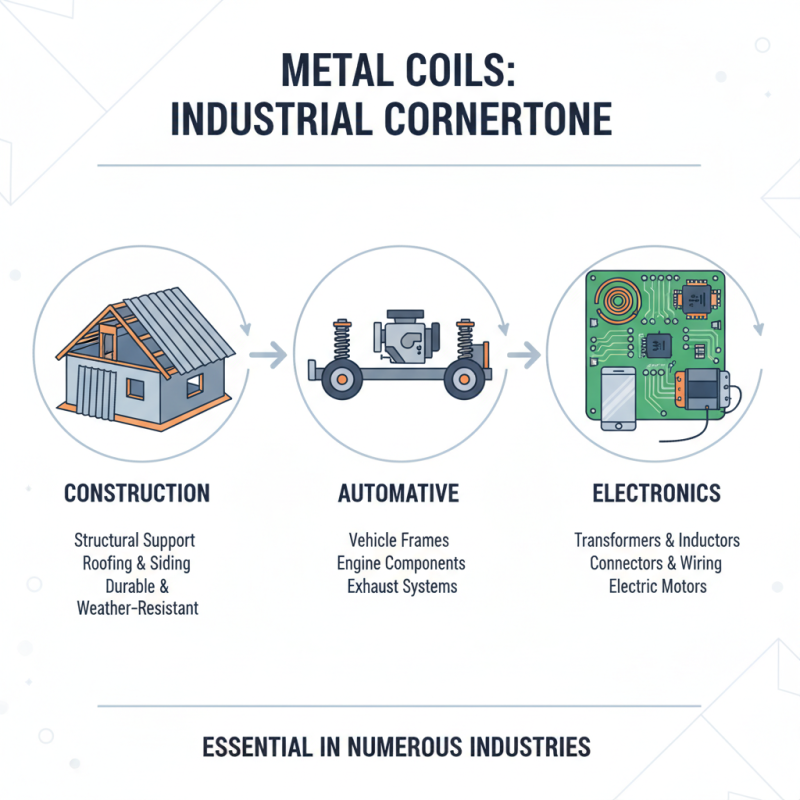

Metal coils play a vital role in numerous industries. They are widely used in construction, automotive, and electronics. In construction, metal coils provide structural support. They are often used in roofing and siding products. These materials are durable and can withstand harsh conditions.

In the automotive industry, metal coils form critical components. They are utilized in making parts like springs and frames. Lightweight metal coils improve fuel efficiency in vehicles. This need for efficiency continues to grow as regulations tighten.

While metal coils have many advantages, there are challenges. Sourcing quality materials can be difficult. Variability in metal properties complicates production. Companies must balance cost and quality, which is not always easy. These issues prompt ongoing improvements in processes and technologies.