In 2026, the use of Carbon Steel Pipe continues to thrive across various industries. This material is known for its strength, making it a popular choice for construction and manufacturing. Carbon Steel Pipe offers durability and resistance to pressure, which are essential in many applications. As industries evolve, the demand for reliable piping solutions grows.

One notable advantage of Carbon Steel Pipe is its affordability. Compared to other materials, it provides excellent performance at a lower cost. However, its susceptibility to corrosion is a concern. Users must consider proper maintenance and protective coatings to prevent rust and degradation.

Moreover, the adaptability of Carbon Steel Pipe is worth mentioning. It can be easily welded and shaped to fit specific needs. Nevertheless, users should weigh the benefits against potential downsides. While it excels in many environments, extreme conditions may require additional consideration. Balancing effectiveness and potential drawbacks is key in choosing Carbon Steel Pipe for future projects.

Carbon steel pipe continues to be a robust choice for structural applications in 2026. Its strength and durability make it ideal for supporting heavy loads. In construction projects, carbon steel pipe can withstand various environmental conditions. It is resistant to extreme temperatures and pressure, ensuring long-lasting performance. Many engineers appreciate its versatility.

However, there are considerations to keep in mind. Carbon steel can be prone to corrosion, especially in moist environments. Regular maintenance is crucial to prevent deterioration. Some structures may require added protection, such as coatings, which can increase costs. The weight of carbon steel pipe can also be a factor; it often requires additional support during installation.

Despite these challenges, the benefits are significant. Carbon steel pipe is affordable compared to other materials, helping to keep budgets in check. Its recyclability is another advantage, aligning with sustainable building practices. Many projects successfully integrate carbon steel due to these factors. While perfect solutions are rare, the unique qualities of carbon steel pipe can lead to enduring structural integrity when properly utilized.

Carbon steel pipes are recognized for their durability and strength. In 2026, the demand for these pipes continues to rise due to their ability to withstand high-pressure applications. According to a recent industry report, carbon steel pipes have a tensile strength that can reach up to 580 MPa. This makes them an ideal choice for construction and industrial projects.

The corrosion resistance of carbon steel is another significant advantage. With proper coatings, carbon steel can last for decades in harsh environments. A study showed that pipes treated with protective layers displayed enhanced longevity by up to 30%. However, neglecting regular inspections can lead to unexpected failures.

**Tips:** Always check for any signs of wear or corrosion. Regular maintenance is crucial to achieve the full benefits of carbon steel pipes. Consider using advanced monitoring technology. It helps prevent potential issues before they escalate.

The adaptability of carbon steel pipes to various applications is impressive. They can be manufactured to different specifications, making them suitable for both residential and industrial use. Despite their strengths, it is vital to evaluate installation techniques. Improper installation can undermine their structural integrity. Regular assessments ensure they perform optimally in any project.

| Benefit | Description | Application Areas |

|---|---|---|

| Durability | Carbon steel pipes are designed to withstand high-pressure applications and harsh environments, providing longevity. | Oil and Gas, Construction |

| Strength | High tensile strength allows carbon steel pipes to carry heavy loads and resist deformation. | Manufacturing, Infrastructure |

| Cost-effectiveness | Carbon steel pipes are generally less expensive to manufacture and maintain compared to other materials. | General Plumbing, HVAC |

| Versatility | Can be used in various applications ranging from water transportation to structural support. | Construction, Agriculture |

| Recyclability | Carbon steel can be recycled repeatedly without losing its mechanical properties, promoting sustainability. | Waste Management, Renewable Energy |

Carbon steel pipes are gaining traction in various industries for their cost-effectiveness. According to a report by the World Steel Association, carbon steel is approximately 20% cheaper than alternative materials like stainless steel. This cost advantage makes it a popular choice among manufacturers and builders. The lower initial investment can significantly impact large-scale projects, where budgets are tight.

In 2026, markets predict a rise in demand for carbon steel pipes. These pipes exhibit durability and strength, making them suitable for high-pressure applications. A study by the American Iron and Steel Institute shows that carbon steel pipes have a lifespan of over 50 years when properly maintained. While they are prone to corrosion, recent advancements in coatings have improved their resilience. Yet, some industries hesitate to switch, debating the long-term maintenance costs involved.

Adopting carbon steel pipes is not without its challenges. Some experts indicate a potential trade-off between cost and performance. Routine inspections become crucial to avoid unexpected failures. Critics argue that, without adequate treatment, the risk of deterioration increases. Balancing upfront costs against future expenditures can be tricky. Companies must weigh these factors carefully before making a choice.

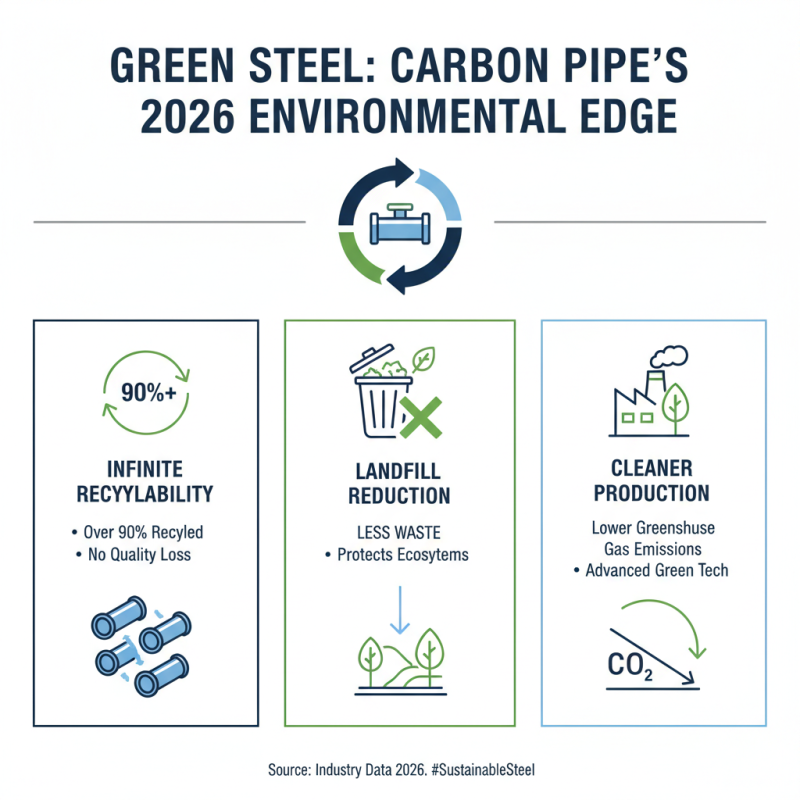

When considering the environmental impact of carbon steel pipe in 2026, benefits are emerging. The lifecycle of carbon steel includes its recyclability. Data suggests that over 90% of carbon steel can be recycled without losing quality. This characteristic significantly reduces waste in landfills. Moreover, steel production has advanced, using cleaner methods that lower greenhouse gas emissions.

However, we must reflect on the extraction processes of raw materials. Mining for iron ore can lead to habitat destruction and significant environmental disturbances. Tips for improvement include sourcing from suppliers committed to sustainable practices. Look for certifications that ensure responsible mining activities.

Sustainability extends to energy use during manufacturing. Renewable energy sources are increasingly being integrated into production processes. In fact, a report by the World Steel Association notes that using renewable energy can cut emissions by up to 30%. It highlights the industry's potential for a greener future. Yet, the transition is slow and requires industry-wide commitment. Finding balance is key.

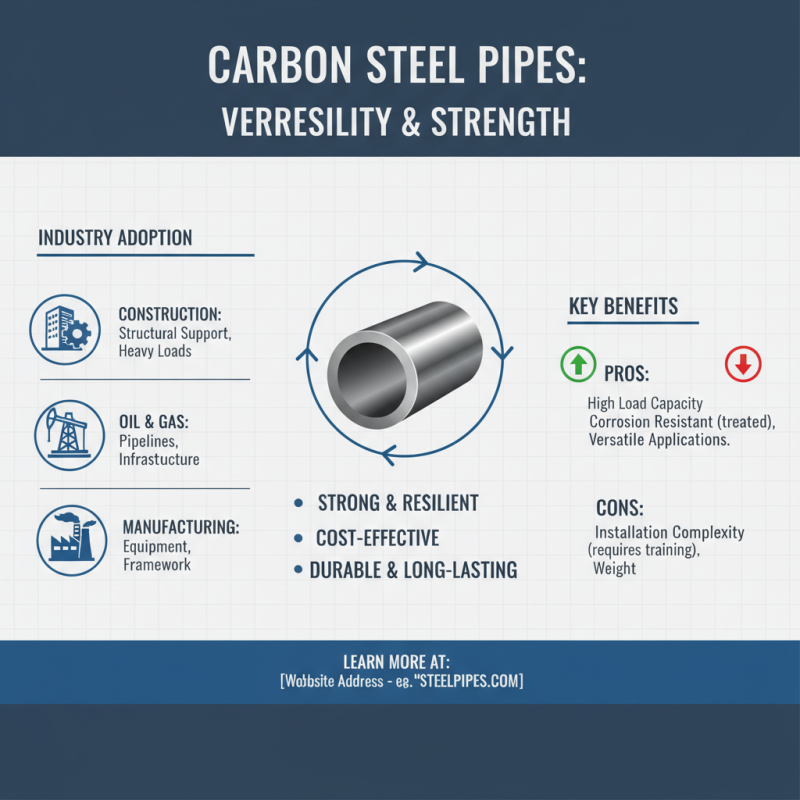

Carbon steel pipes are gaining popularity in multiple industries for their versatility. In construction, their strength and resilience make them ideal for structural support. Many buildings rely on carbon steel for stability. This material can handle heavy loads, which is crucial for high-rise structures. Yet, some industries find them difficult to install without proper training.

In manufacturing, carbon steel pipes adapt to various processes. They are used in plumbing systems and machinery. Their durability helps minimize maintenance. However, corrosion can be a concern. Some manufacturers overlook this issue, leading to unexpected failures. Addressing this risk properly is essential for long-term performance.

Additionally, carbon steel pipe can be customized for specific applications. Different thicknesses and diameters allow flexibility in design. This adaptability is beneficial for energy production, especially in oil and gas sectors. Change is constant, and so are the requirements. Companies need to reflect on how they select materials. Choices today will impact the future landscape of production and infrastructure.