Cold Rolled Sheets have become essential in various industrial applications. Industry expert John Smith once remarked, “Cold Rolled Sheets enhance product quality and precision.” This highlights their significance in sectors like automotive, construction, and electronics.

Manufacturers prefer Cold Rolled Sheets for their consistent thickness and superior surface finish. These sheets are cold-formed, which improves their strength. This enhanced durability makes them suitable for parts requiring high resistance and low weight.

However, the process can lead to challenges. Cold Rolled Sheets may warp or require careful handling to avoid scratches. Some industries may overlook these aspects. Understanding these limitations is crucial for optimal use. The promise of Cold Rolled Sheets is substantial, but so are the considerations in their application.

Cold rolled sheets are essential in many industries due to their unique characteristics. They are created by passing steel through rollers at room temperature. This process leads to a smoother surface finish and tighter tolerances. As a result, cold rolled sheets are often preferred for applications requiring precision.

These sheets possess excellent formability, making them suitable for complex shapes. They are often used in automotive parts, appliances, and industrial machinery. However, while they boast superior performance, they can also be more prone to corrosion. This limitation can be a challenge for certain environments.

Durability is another important feature. Cold rolled sheets offer high strength-to-weight ratios. Yet, they may require additional coatings for increased longevity. Designers must consider these factors when selecting materials. The balance between performance and potential drawbacks can shape project outcomes.

Cold rolled sheets are essential in numerous industries due to their unique properties. These sheets have a smooth finish and precise dimensions, making them ideal for manufacturing. The automotive sector is one of the largest users of cold rolled sheets. According to a recent industry report, about 60% of automotive body structures rely on cold rolled steel. This ensures vehicles are lightweight yet robust.

The construction industry also benefits significantly from cold rolled sheets. These materials are used for roof panels, wall cladding, and even in heavy-duty applications. Data from the Steel Construction Institute indicates that cold rolled products can reduce material waste by up to 30%. However, manufacturers should consider the potential for surface defects during production. Quality control measures are necessary to avoid issues that could affect the structural integrity.

Moreover, the appliance industry is seeing increased use of cold rolled sheets. Products like refrigerators and washing machines require high strength and aesthetic appeal. Research shows that around 40% of appliances use cold rolled steel in their fabrication. Despite these benefits, it is vital for manufacturers to reflect on sustainability practices. The high energy consumption during processing calls for innovations that improve eco-efficiency in production.

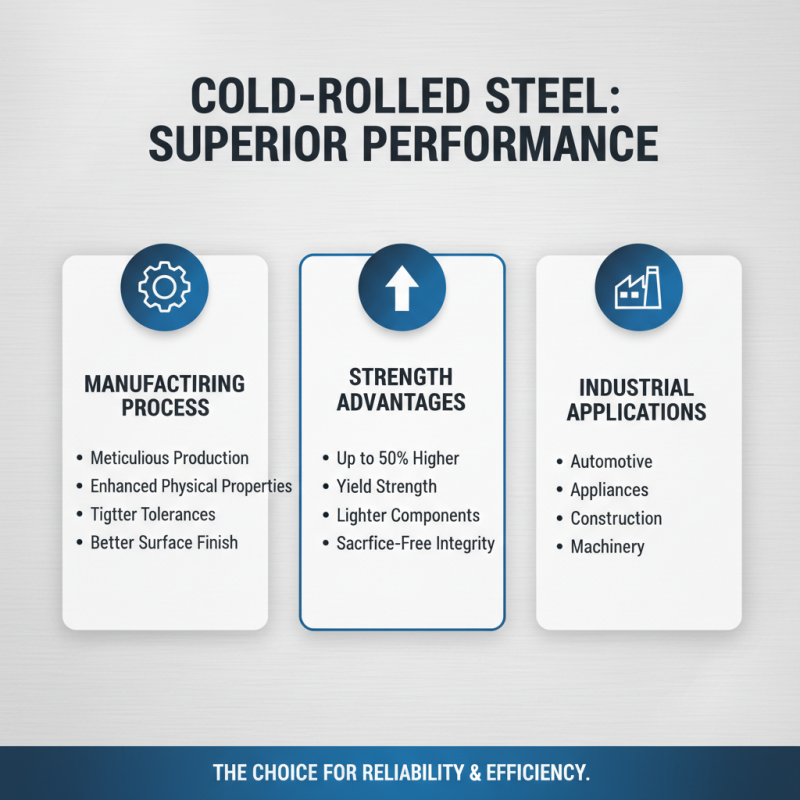

Cold rolled sheets have distinct advantages over other steel types in various industrial applications. These sheets are produced through a meticulous process that enhances their physical properties. This method results in a tighter tolerance and better surface finish. According to industry reports, cold-rolled steel can have a yield strength up to 50% higher than hot-rolled alternatives. This increased strength allows manufacturers to create lighter components without sacrificing integrity.

One significant benefit of cold rolled sheets is their excellent formability. They can be easily shaped into complex components required in sectors like automotive and construction. A report by the American Iron and Steel Institute states that these sheets account for over 35% of total steel sheet consumption in the U.S. Yet, many industries still overlook the fact that cold rolled sheets can be more costly upfront. This can lead to hesitations in their use, despite the long-term benefits.

The aesthetic appeal of cold rolled sheets also plays a crucial role. Their smooth surface is free from visible defects, which is essential for applications like appliances and interior design. However, challenges remain; not all applications may need the enhanced properties of cold rolled sheets, leading to over-engineered products. Balancing cost and performance is key for manufacturers considering their options.

Cold rolled sheets have transformed modern engineering. These sheets offer enhanced strength and surface finish, making them versatile. They are lightweight yet durable, ideal for various applications in construction and manufacturing. Designers appreciate their ability to be easily shaped and formed into intricate designs.

Innovative applications include automotive parts, where precision is crucial. Cold rolled sheets are used in chassis, body panels, and supports. These components benefit from reduced weight, which improves fuel efficiency. In electronics, they contribute to reliable housing for devices. Their smooth surface finishes help reduce wear and tear on internal parts.

Tip: Consider the thickness of cold rolled sheets. Thicker sheets provide better durability, while thinner ones offer more flexibility in design. It's essential to balance strength with application needs. Always assess the end use. Avoid using overly thin sheets for heavy-duty requirements, as they may warp or fail.

| Application Area | Advantages | Common Uses |

|---|---|---|

| Automotive Industry | High strength and ductility | Body panels, chassis components |

| Construction | Excellent surface finish | Structural beams, roofing |

| Appliances | Formability and weldability | Refrigerators, washing machines |

| Electronics | Precision manufacturing | Computer cases, circuit boards |

| Furniture | Durability and aesthetics | Metal tables, chairs |

Cold rolled sheet production is evolving rapidly. Industry reports suggest that the global cold rolled steel market is expected to grow substantially. By 2027, the market could reach USD 400 billion. This growth is driven by rising demand in construction and automotive sectors. A shift towards lightweight and high-strength materials is evident, with cold rolled sheets becoming crucial in design.

More manufacturers are exploring automation in cold rolling processes. Advanced technologies, like AI and machine learning, are being integrated. This could enhance production efficiency by 25%. However, some companies hesitate to adopt these innovations due to costs and training needs. Environmental regulations are also tightening. Companies face challenges in meeting standards while maintaining productivity.

The focus on sustainability is prominent. Future trends indicate a push for greener processes in cold rolled sheet production. Companies are researching eco-friendly coatings and recycling methods. However, the industry still grapples with high energy consumption and waste generation. Addressing these issues is essential for sustainable growth. While opportunities abound, the path forward requires serious consideration of environmental impacts.