When it comes to selecting the right stainless steel plate for your project, the decision can be daunting. Experts like John Doe, a renowned specialist in metallurgy, emphasize, "The right stainless steel plate can make or break your project." This statement resonates in various industries, from construction to culinary.

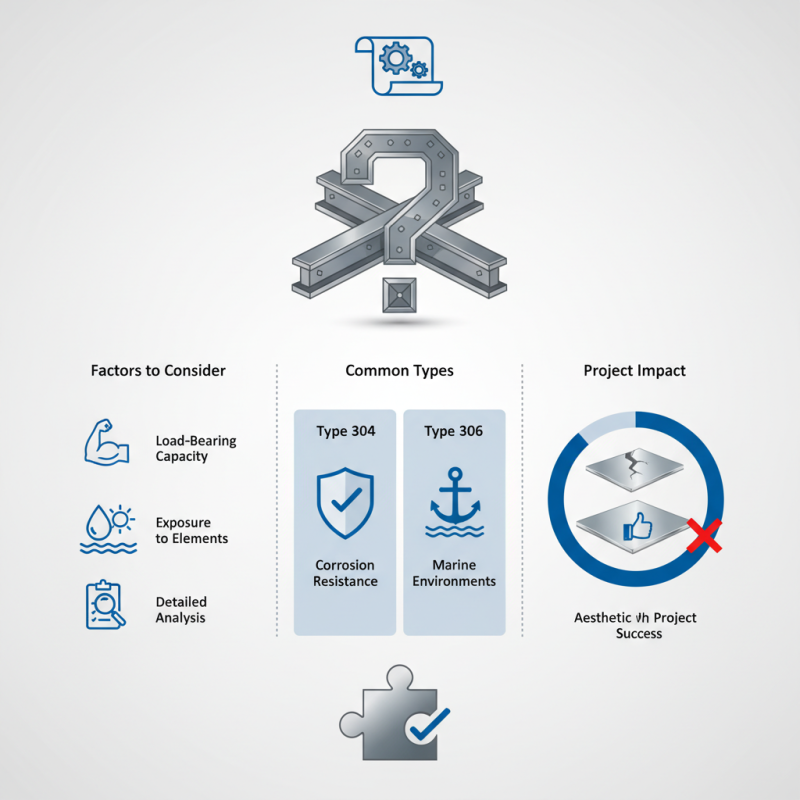

Stainless steel plates come in various grades, sizes, and finishes. Each selection impacts durability and aesthetics. For instance, a Type 304 plate is more resistant to corrosion, while a Type 316 plate excels in marine environments. Yet, making the right choice isn't always straightforward. Consider your project requirements carefully. Reflect on factors like load-bearing capacity and exposure to elements.

Often, individuals overlook the importance of a detailed analysis. This oversight can lead to unsatisfactory results. An ill-suited stainless steel plate may cause structural failure or aesthetic issues. Taking the time to assess needs could prevent such pitfalls. Always remember, the right stainless steel plate isn't just about specifications, but also about how it aligns with your specific project goals.

When selecting a stainless steel plate, understanding the different grades is crucial. Stainless steel comes in various grades, each with unique properties. For instance, austenitic stainless steel, like grade 304, offers excellent corrosion resistance. It's easy to shape and is commonly used in kitchen appliances. Its shiny appearance is appealing, but it may not be as strong as some industrial needs require.

On the other hand, martensitic stainless steel, such as grade 410, is known for its hardness. It's often used in applications that need durability, like cutlery and industrial blades. However, its corrosion resistance is less than that of austenitic grades. When choosing, consider the environment. Will the plate face moisture or harsh chemicals? Reflect on whether you need a flexible option or something more robust. Sometimes, the right choice may be unclear, leading to potential rework down the line. Analyzing the specific requirements of your project is essential.

Choosing the right stainless steel plate for your project requires careful consideration of project requirements and specifications. First, identify the environmental factors. Will the plate face extreme temperatures or corrosive substances? According to a recent industry report, 60% of stainless steel failures are due to improper material selection. Such mistakes can lead to costly repairs and delays.

Next, consider the mechanical properties needed for your project. Different grades of stainless steel offer varying strength and ductility. For example, the AISI 304 grade is often chosen for its good corrosion resistance and weldability. However, it might not suffice for high-stress applications. In contrast, AISI 316 is more suitable for marine environments due to its higher molybdenum content. A clear understanding of these properties can prevent future issues.

Thickness and dimensions also matter. Ensuring the right thickness might save money upfront but could cause structural failures later. The industry average indicates that projects underestimate thickness needs by 30%, leading to safety concerns. Such details must be defined early on, reflecting the project's scope and intended use. Too often, these specifications are glossed over in initial planning.

| Criteria | Description | Considerations | Common Grades |

|---|---|---|---|

| Corrosion Resistance | Ability to withstand corrosive environments | Identify exposure to chemicals or saltwater | 304, 316 |

| Strength | Ability to withstand stress without failure | Determine load requirements and conditions | 309, 310 |

| Weldability | Ease of joining stainless steel plates together | Consider welding techniques and requirements | 304L, 316L |

| Surface Finish | Type of finish affects aesthetics and functionality | Decide on brushed, mirror, or industrial finishes | No. 4, No. 8 |

| Thickness | Measured in gauge or millimeters, affects strength and weight | Assess weight constraints and required durability | 1/16", 1/8", 1/4" |

When choosing a stainless steel plate, understanding its properties is crucial. Stainless steel comes in various grades, each with unique characteristics. For instance, austenitic stainless steels are known for their excellent corrosion resistance and formability. This makes them suitable for kitchen equipment. However, they may not withstand high temperatures well.

Corrosion resistance varies greatly. Some grades contain higher levels of nickel or molybdenum, which enhance resistance to oxidation. If your project involves exposure to harsh chemicals, selecting a plate with appropriate resistance can save future headaches. On the other hand, lower-grade options may lead to rust and deterioration. Limited knowledge of grades could result in costly mistakes.

Mechanical properties also play a role. Tensile strength, hardness, and ductility are vital for different applications. The right choice can impact the durability of the final product. Testing is essential to ensure the plate meets your requirements. Missing this step could lead to performance issues later on. Always consider how the material's properties align with your project's specific demands.

When selecting stainless steel plates for a project, cost and availability play crucial roles. Stainless steel can vary significantly in price depending on factors like grade and thickness. Higher grades, such as 316, often cost more. Consider the specific properties you need, as the correct choice can save you money in the long run.

Availability is also a key factor. Depending on your location, some grades might be easier to find. Local suppliers may have limited stock. Certain types of stainless steel plates could take weeks to arrive if they’re special ordered. This could delay your project and increase costs. Always check with suppliers about lead times before you decide.

Be cautious when estimating your budget. Costs can fluctuate due to market demand. Unexpected price increases can happen, so allow some flexibility in your budget. Remember, the right plate not only fits your project requirements but also aligns with your financial expectations. Ignoring these factors could lead to costly mistakes.

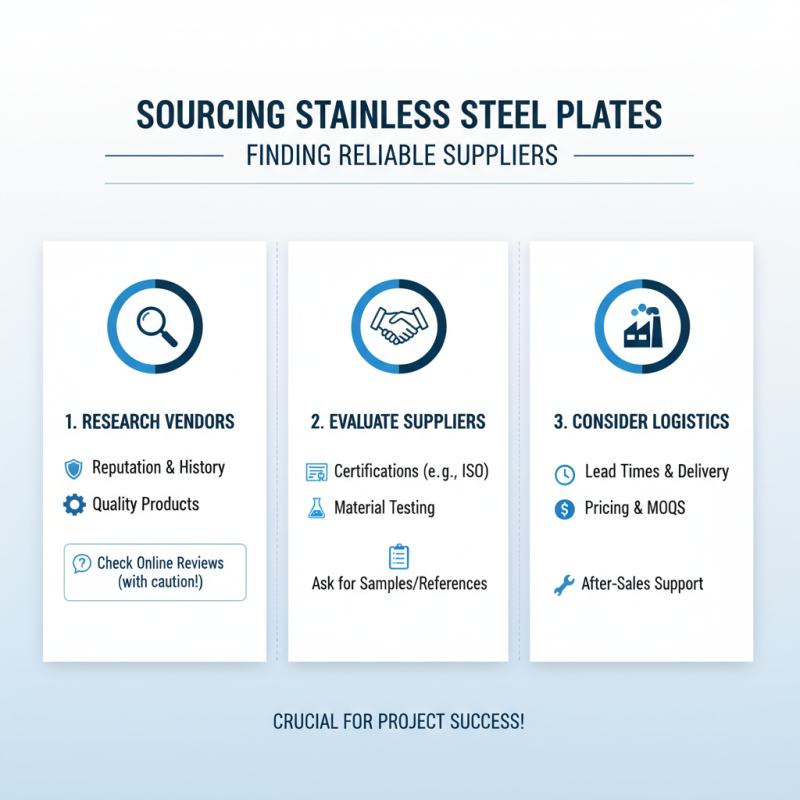

When sourcing stainless steel plates for your project, choosing reliable suppliers is crucial. Start by researching potential vendors. Look for companies with a solid reputation and a history of quality products. Online reviews can provide insights, but remember they may not tell the whole story.

Engaging directly with suppliers is essential. Ask about their sourcing methods. A transparent supplier is more likely to offer high-quality materials. Look for certifications that demonstrate compliance with industry standards. Don't hesitate to request samples. This small step can reveal a lot about the material's quality.

Keep in mind that price is not everything. The lowest price can often lead to issues down the line. Be wary of offers that seem too good to be true. Sometimes, these are shortcuts that compromise quality. Evaluate your project needs against the supplier’s offerings. It’s okay not to get it right the first time. Reflect on any past mistakes and adjust your strategy accordingly. This learning process helps refine your decisions for future projects.