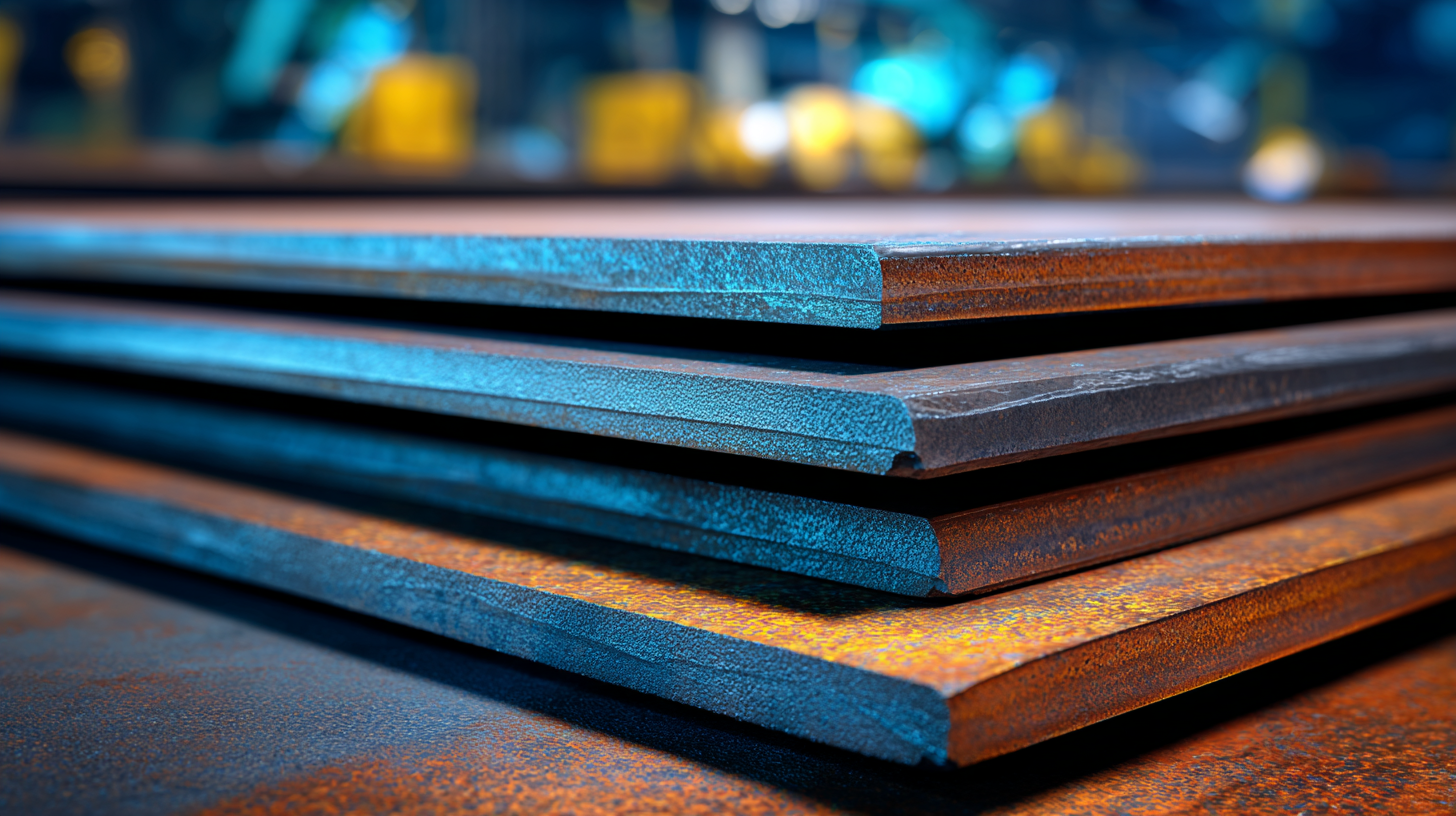

In the realm of industrial applications, Carbon Steel Plates play a pivotal role due to their unique properties and versatility. According to a report by MarketsandMarkets, the global carbon steel plate market is projected to reach USD 136.2 billion by 2026, witnessing a CAGR of 4.2% from 2021. This growth can be attributed to the escalating demand across various sectors, including construction, automotive, and energy, where strength, durability, and cost-effectiveness are paramount. Additionally, data from ResearchAndMarkets indicates that the increased use of high-strength low-alloy (HSLA) carbon steel plates is revolutionizing manufacturing practices by enhancing performance while reducing weight. Understanding the essential characteristics and applications of Carbon Steel Plates is crucial for industry professionals aiming to leverage these materials for optimal efficiency and innovation in their operations.

Carbon steel plates are widely recognized for their versatility and strength, making them a staple in various industrial applications. The composition of carbon steel primarily consists of iron and carbon, with the carbon content typically ranging from 0.05% to 2.0%. This variation in carbon levels significantly influences the steel's hardness, tensile strength, and ductility. Low-carbon steel plates, for instance, are known for their excellent weldability and formability, making them ideal for construction and automotive parts. In contrast, higher carbon steel plates tend to exhibit increased hardness and wear resistance, which is advantageous for manufacturing tools and machinery components.

Carbon steel plates are widely recognized for their versatility and strength, making them a staple in various industrial applications. The composition of carbon steel primarily consists of iron and carbon, with the carbon content typically ranging from 0.05% to 2.0%. This variation in carbon levels significantly influences the steel's hardness, tensile strength, and ductility. Low-carbon steel plates, for instance, are known for their excellent weldability and formability, making them ideal for construction and automotive parts. In contrast, higher carbon steel plates tend to exhibit increased hardness and wear resistance, which is advantageous for manufacturing tools and machinery components.

In addition to carbon, other elements such as manganese, chromium, and molybdenum may be present, enhancing the steel's overall properties. Manganese, for example, helps improve hardness and tensile strength, while chromium enhances corrosion resistance. Understanding these compositional nuances is crucial for engineers and manufacturers when selecting the appropriate carbon steel plate for specific applications. The manipulation of these elements allows for tailored properties, enabling industries to optimize the performance and durability of their products in demanding environments.

When assessing carbon steel for industrial applications, it’s crucial to understand the differences among the various types. Carbon steel can be categorized into low, medium, and high carbon steel. Low carbon steel, with a carbon content of up to 0.25%, is renowned for its excellent malleability and weldability, making it ideal for structures and manufacturing processes. On the other hand, medium carbon steel, which contains 0.25% to 0.60% carbon, offers a balance of strength and ductility, making it suitable for components that experience moderate tension and impact. Finally, high carbon steel, with a carbon content exceeding 0.60%, provides exceptional hardness and wear resistance, suitable for tools and high-stress applications.

Tips: When choosing the right carbon steel for your project, consider the environment and stresses the material will face. For structural applications, low carbon steel may be the best choice, while high carbon steel is ideal for parts requiring durability. Additionally, always consult with a materials engineer to ensure compatibility with your specific industrial needs, as the right selection can mean longevity and performance in your applications.

Carbon steel plates offer significant advantages for construction, primarily due to their durability and resilience. In the context of climate-conscious building practices, these plates facilitate faster erection times, allowing projects to be completed more efficiently while also minimizing embodied carbon. Research highlights that innovative steel structures not only enhance construction speed but also lead to sustainable design choices that align with modern environmental standards.

Additionally, advancements in construction technology, such as the use of carbon emission assessments for building materials, underscore the growing emphasis on reducing overall carbon footprints. Techniques like optimization analysis of high-rise steel structures and the utilization of advanced materials demonstrate how carbon steel plates can be integral to achieving sustainable building solutions. By focusing on these key advantages, carbon steel plates are positioned as essential components in the evolution of construction practices aimed at promoting a circular economy and addressing climate change.

| Insight | Description | Key Advantage | Application |

|---|---|---|---|

| Strength | Carbon steel plates possess high tensile strength and durability. | Ideal for heavy-load applications. | Construction, shipbuilding. |

| Cost-Effectiveness | Relatively low cost compared to other materials like stainless steel. | Reduces overall project costs. | Manufacturing, automotive industry. |

| Weldability | Easy to weld and fabricate, allowing for versatile designs. | Facilitates complex structures. | Construction, machinery. |

| Corrosion Resistance | Can be treated or coated to resist corrosion. | Enhances lifespan of structures. | Pipelines, bridges. |

| Versatility | Available in various grades and thicknesses for different requirements. | Applicability across diverse industries. | From construction to engineering. |

| Thermal Conductivity | Excellent thermal conductivity, making it suitable for heat exchangers. | Efficient heat management. | Power plants, HVAC systems. |

| Formability | Good formability allows for bending and shaping without cracking. | Flexible to design needs. | Manufacturing, artistic designs. |

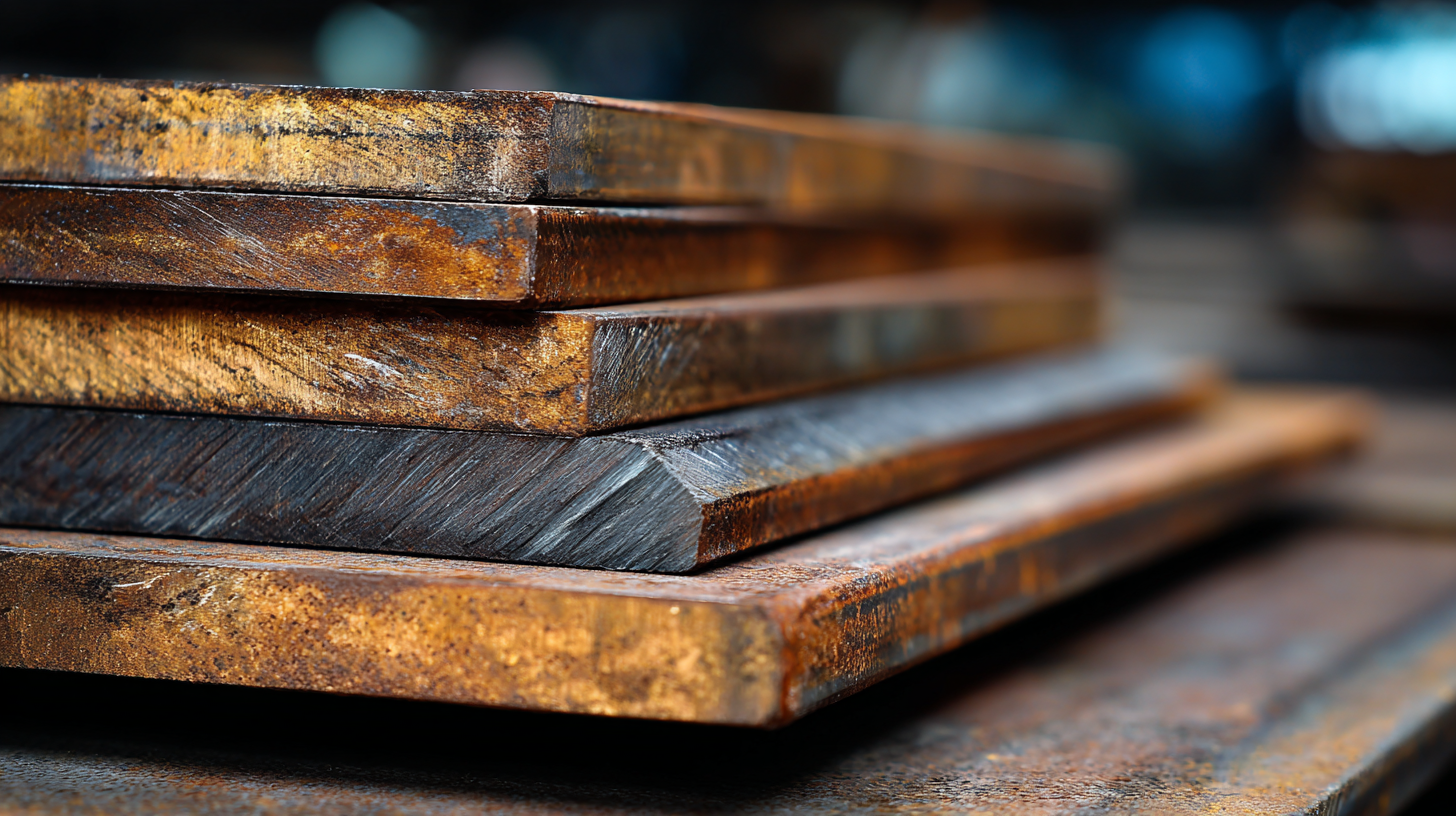

When it comes to maintaining and caring for carbon steel plates in industrial settings, understanding their unique properties and requirements is essential. Carbon steel plates are favored for their strength and versatility, but they are also susceptible to corrosion and wear if not properly cared for. Industry reports indicate that nearly 20% of structural failures in manufacturing can be attributed to inadequate maintenance, emphasizing the importance of regular inspections and protective treatments.

To extend the lifespan of carbon steel plates, adopting a proactive maintenance strategy is crucial. This includes regular cleaning to remove contaminants and applying protective coatings that can significantly reduce the risk of rust formation. According to a survey by the National Association of Corrosion Engineers, using anti-corrosion treatments can decrease maintenance costs by up to 30%. Additionally, ensuring optimal storage conditions—such as maintaining dry environments and implementing proper stacking techniques—can further enhance the durability of these plates in industrial applications. Implementing these measures not only protects the investment in carbon steel plates but also ensures safety and efficiency in industrial operations.

Carbon steel plates are widely utilized across various industrial applications due to their durability and strength. One common use is in the construction sector, where these plates serve as key components in structural frameworks. Their ability to withstand high levels of stress and pressure makes them ideal for buildings, bridges, and commercial infrastructures. Additionally, carbon steel plates are preferred in manufacturing heavy machinery, as they provide the necessary resilience to endure rigorous operations.

Another prominent application of carbon steel plates is in the automotive industry. They are essential in the production of body panels, chassis components, and other structural parts, ensuring vehicle safety and performance. Furthermore, carbon steel plates are also employed in the oil and gas sector, where they are used for constructing pipelines and pressure vessels, as they effectively resist corrosion and fatigue under demanding conditions. The versatility of carbon steel plates allows them to meet the diverse needs of multiple industries, reinforcing their importance in modern manufacturing and construction processes.

This chart illustrates the common applications of carbon steel plates in various industries, highlighting their significance and usage across different sectors.