Round pipes are essential in construction. They have a variety of applications. These versatile components play a critical role in various structures. Round pipes come in different materials, such as steel, PVC, and copper. Each material has unique properties. They suit specific construction needs.

In plumbing, round pipes transport water and waste. They connect different fixtures, ensuring proper water flow. In structural applications, round pipes provide support and stability. They are often used in scaffolding and frameworks. This adds strength to buildings and bridges.

However, using round pipes can be challenging. Sizing and material choice are crucial for success. Poor decisions can lead to leaks or structural failures. It's important to consider these factors carefully. Round pipes are vital, but they require thoughtful planning and execution.

Round pipes are cylindrical tubes commonly used in construction. They are made from various materials, including metal, plastic, and concrete. Their shape provides strength and resilience, making them ideal for different applications. A round pipe’s geometry allows for efficient fluid flow and distribution, which is critical in plumbing and drainage systems.

In construction, round pipes serve many purposes. They can be used for structural support, such as columns or beams. Their rounded shape helps distribute stress evenly, reducing the risk of weaknesses. Additionally, round pipes are often favored in HVAC systems for air distribution. The smooth interior allows for increased airflow, minimizing energy loss.

Despite their many benefits, round pipes can present challenges. Installation may require specialized tools, which can increase costs. Additionally, their circular geometry can make them difficult to fit in tight spaces. It’s essential to evaluate the site conditions before choosing round pipes. Understanding these factors can help avoid potential problems in the construction process.

Round pipes serve various purposes in the construction industry. Their versatility is largely attributed to the materials from which they are made. Common options include steel, plastic, and copper, each with unique properties. Steel pipes are sturdy, suitable for heavy-duty applications. They frequently support structures and transport fluids. Their strength can also be a double-edged sword; improper handling can lead to safety hazards.

Plastic pipes, on the other hand, are lightweight and resistant to corrosion. They are often used in drainage systems. While these pipes are easier to install, they may not withstand extreme temperatures and pressure as well as steel. Builders should weigh these factors when making a material choice.

Copper pipes are known for their durability and reliability. They are especially popular in plumbing systems. However, the cost can be a significant barrier. It’s essential to assess the budget before choosing copper. Each material has its strengths and weaknesses, and understanding them can lead to better construction outcomes. Knowing the right context for each type can enhance project efficiency.

| Material | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|

| PVC | Drainage systems, plumbing | Corrosion-resistant, lightweight | Not suitable for high temperatures |

| Steel | Structural framework, pipelines | High strength, durable | Susceptible to rust |

| Copper | Water supply, heating systems | Excellent thermal conductivity, corrosion-resistant | Expensive, challenging to work with |

| Aluminum | Ventilation systems, construction scaffolding | Lightweight, resistant to corrosion | Lower strength compared to steel |

| Fiber Reinforced Plastic (FRP) | Chemical processing, wastewater treatment | Chemical resistance, lightweight | Can be more expensive than traditional materials |

Round pipes are essential components in various construction projects. Their shape allows for effective fluid flow, making them ideal for plumbing systems. These pipes often transport water and other liquids. In places where space is limited, round pipes fit perfectly. They are easy to install and manage, saving time on the job site.

In structural applications, round pipes add strength to frameworks. They distribute loads evenly across structures. This is especially useful in bridges and towers. Additionally, round pipes can be used for railings and supports, enhancing safety. Their versatility means they can also be found in HVAC systems, where they carry air.

However, choosing the right size and material is crucial. Oversized pipes can be excessive and hard to handle. On the other hand, undersized pipes may cause pressure issues. Construction professionals must carefully consider these aspects. Balancing aesthetics and functionality is often a challenge. Mistakes can lead to costly changes later in the project.

Round pipes are popular in construction due to their unique advantages. One major benefit is their structural efficiency. According to a report by the American Institute of Steel Construction, round pipes can withstand high pressure. Their shape distributes stress evenly. This makes them ideal for load-bearing applications, like in support beams.

The circular shape also allows for easier fluid flow. In plumbing and HVAC systems, round pipes minimize turbulence. Data from the International Plumbing Code shows that they can reduce energy costs by up to 15%. This efficiency is crucial in large buildings where water and air circulation is vital. With less resistance, round pipes help systems operate smoothly.

However, there are shortcomings to consider. While round pipes excel in some areas, they may not be suitable for all spaces. In tight corners, other shapes, like square pipes, can fit better. The design team should evaluate the project needs. Selecting the right pipe shape is not a one-size-fits-all decision. It requires careful reflection on project specifications and constraints.

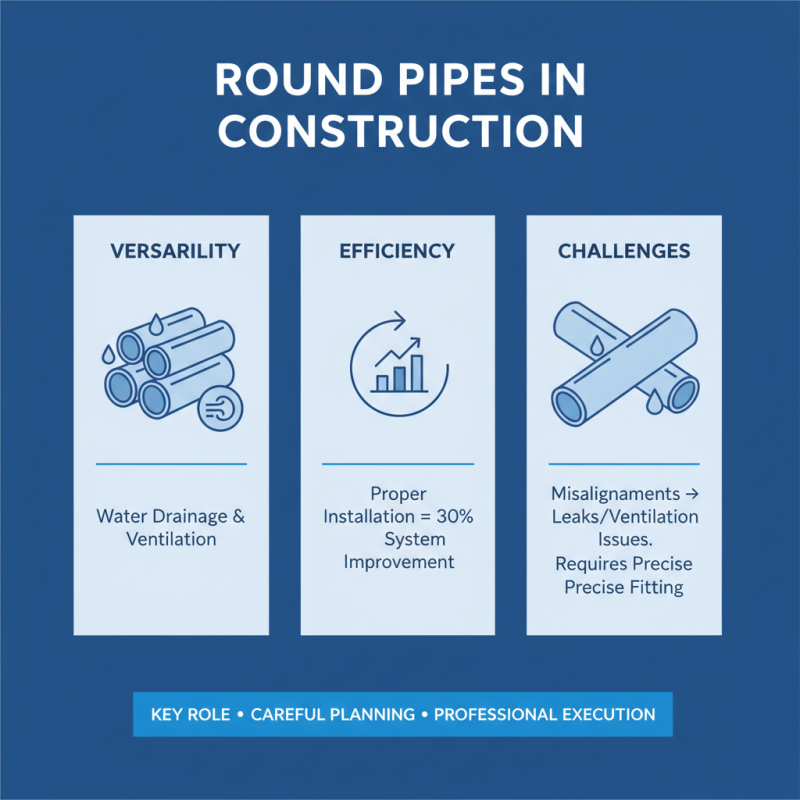

Round pipes play a crucial role in construction. Their installation demands careful planning and execution. From water drainage systems to ventilation, round pipes are versatile. A recent study suggests that proper pipe installation improves system efficiency by 30%. However, installing these pipes is not always straightforward. Inexperienced workers can lead to misalignments. This may result in water leaks or ventilation issues. Professionals need to ensure precise fittings.

Maintenance is equally essential for round pipes. Regular inspections can prevent costly damage. The American Society of Civil Engineers reports that up to 15% of construction-related expenses stem from pipe maintenance. Simple measures like cleaning and checking for corrosion can prolong a pipe's life. Neglecting maintenance could lead to severe complications, such as pipe bursts, which can disrupt construction timelines. It's vital to create a maintenance schedule and stick to it for optimal performance.