Seamless pipes play a pivotal role in various industries, offering unique benefits that address specific needs. According to industry reports, the global seamless pipe market is expected to grow substantially, reaching an estimated value of $34 billion by 2027, with a CAGR of over 6%. This growth is driven by the demand for high-strength and corrosion-resistant materials, particularly in oil and gas applications.

One key advantage of seamless pipes is their enhanced durability. Without welds, they are less prone to failure under pressure. This characteristic is particularly crucial in high-stress environments, such as offshore drilling. However, some industry experts argue that manufacturing seamless pipes can be more energy-intensive compared to welded alternatives. This raises questions about sustainability in production processes.

In construction and manufacturing, seamless pipes are favored for their reliability and performance. The aerospace sector, which demands precision, increasingly relies on these pipes. There is still room for improvement in production techniques to reduce costs and environmental impact. As we explore the myriad uses and benefits of seamless pipes, acknowledging these complexities will be essential for future innovations.

Seamless pipes have unique characteristics that set them apart. They are produced without any welding, which greatly enhances their strength. This manufacturing process begins with solid round steel bars. These bars are heated and pierced to create a hollow tube. The seamless design offers a continuous structure, reducing the likelihood of failure.

When it comes to manufacturing, precision is key. The temperature and pressure must be controlled accurately. Any deviation can lead to flaws in the pipe. After forming, the pipes undergo heat treatment. This improves their mechanical properties, making them suitable for various applications.

Tips: Regular inspections during production are crucial. They help catch defects before the pipes go out. Also, consider the environment where the pipes will be used. Different conditions may require specific types of seamless pipes. Choosing the right material can prevent future issues.

Understanding the seamless pipe manufacturing process highlights its importance across industries. It serves as a reminder of the balance between quality control and efficient production. Taking the time to assess these factors can lead to better results.

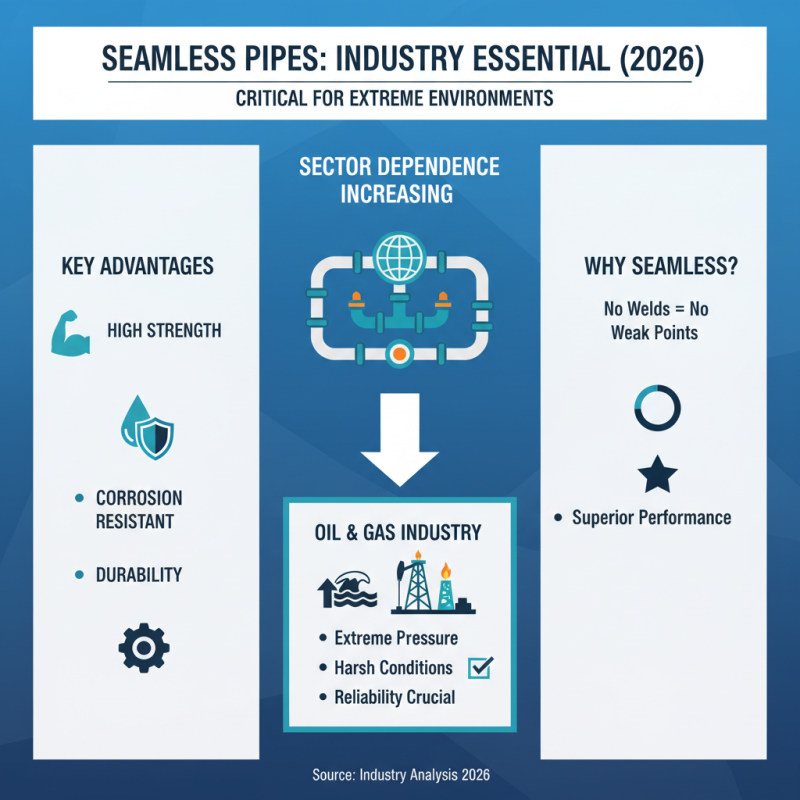

Seamless pipes have become essential in various industries. In 2026, key sectors increasingly depend on these pipes for their unique benefits. The oil and gas industry stands out. It requires high-strength materials that can withstand extreme pressure. Seamless pipes fit this need perfectly. They offer durability and resistance to corrosion.

Another significant sector is construction. Seamless pipes are vital in structural applications. They provide strength without joints that can weaken the structure. This is crucial for skyscrapers and bridges. Moreover, the automotive industry also utilizes seamless pipes. These pipes are used in exhaust systems and hydraulic lines. They enhance performance and safety.

However, not all seamless pipes are perfect. Their production can be costly. This might push smaller companies to seek alternatives. The reliance on seamless pipes does raise questions about sourcing and sustainability. It's essential to address these issues as demand grows.

Seamless pipes offer distinct advantages, especially for fluid transport. One of the major benefits is their structural integrity. Unlike welded pipes, seamless pipes are forged from a solid block of material. This results in uniform strength, making them ideal for high-pressure applications. Users can rely on them in critical situations.

Another key advantage lies in their resistance to corrosion. Seamless pipes often withstand hostile environments better. This property is crucial in industries like oil and gas, where exposure to harsh chemicals is frequent. With seamless options, maintenance costs may decrease significantly.

However, seamless pipes might come with a higher upfront cost. It’s essential to evaluate the long-term benefits versus initial expenses. Balancing these factors is critical for informed decision-making. Some projects may not need the advantages that seamless pipes provide. Careful consideration can help avoid unnecessary expenditures while ensuring quality transport solutions.

When comparing seamless pipes to welded pipes, key differences emerge. Seamless pipes boast a uniform structure, making them stronger under pressure. This quality is crucial in industries like oil and gas. In contrast, welded pipes tend to have a seam where two pieces connect. This often weakens the overall integrity. Therefore, seamless pipes are preferred for high-stress applications.

However, welded pipes have their advantages. They are generally less expensive to produce. This can make them appealing for projects with tighter budgets. Their availability is also higher, making them easier to source. Yet, depending on the intended use, this lower cost might come at the expense of durability. The decision of which pipe to use should consider both budget and application.

In many situations, the choice may not be clear-cut. Innovative projects might require both pipe types in different sections. Choosing seamlessly designed pipes for critical areas could enhance safety, while more cost-effective welded options may suffice for non-critical sections. This nuanced approach addresses the myriad needs of engineering projects. Balancing cost with reliability is always a challenge in material selection.

The seamless pipe industry is evolving rapidly. Innovations in technology are shaping future applications. According to a report by MarketsandMarkets, the global seamless pipe market is projected to reach $70 billion by 2026, driven by growing sectors such as oil and gas. These pipes offer advantages like high resistance to pressure and corrosion, making them ideal for critical applications.

Emerging trends include the use of advanced materials. For example, the adoption of high-strength alloys will enhance durability. The construction industry is increasingly looking for lightweight options that do not compromise strength. Data suggests that oil and gas sectors will account for approximately 47% of seamless pipe usage by 2025. This highlights the need for improved manufacturing techniques to meet rising demands.

Environmental concerns also play a critical role. The shift towards sustainable practices is forcing companies to rethink their production processes. Innovations like 3D printing are entering the market. However, the scalability remains uncertain. There are challenges in achieving the desired quality and consistency in finished products, prompting ongoing discussions among industry experts. These reflections on current capabilities indicate the need for continuous improvement and adaptation.