0102030405

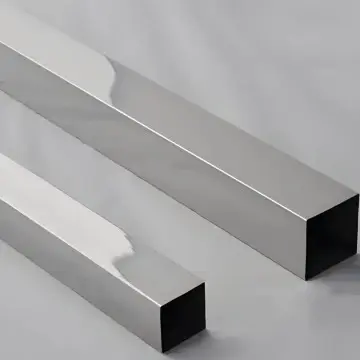

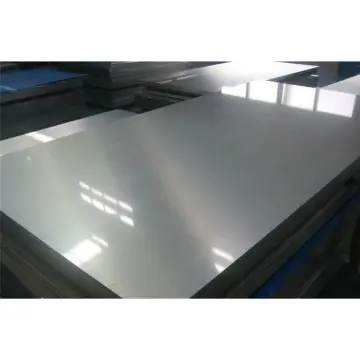

Hot Rolled Stainless Steel Plate

Product Description

Hot rolled steel plate is a steel plate made by rolling steel ingots or continuous casting billets through multiple passes in a rolling mill at high temperatures, with a thickness generally above 1.2mm. Hot rolled steel plates have high plasticity and weldability, but low hardness, making them suitable for the production of general and welded structures.

Materials

Stainless steel material: Hot rolled stainless steel plates usually use different types of stainless steel materials such as 304, 316, 321, etc.

304 stainless steel: has good corrosion resistance and formability, suitable for general environment.

316 stainless steel: Contains molybdenum, has stronger corrosion resistance and is suitable for marine and chemical environments.

321 stainless steel: With the addition of titanium, it has good high temperature resistance and is suitable for high temperature environments.

Materials

Stainless steel material: Hot rolled stainless steel plates usually use different types of stainless steel materials such as 304, 316, 321, etc.

304 stainless steel: has good corrosion resistance and formability, suitable for general environment.

316 stainless steel: Contains molybdenum, has stronger corrosion resistance and is suitable for marine and chemical environments.

321 stainless steel: With the addition of titanium, it has good high temperature resistance and is suitable for high temperature environments.

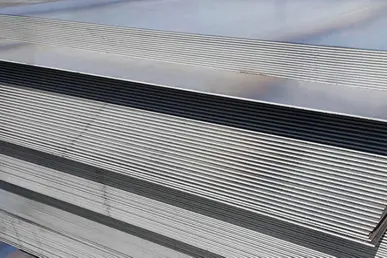

Specifications

Thickness: The thickness of hot-rolled stainless steel plates is usually between 3mm and 100mm, and the specific thickness can be customized according to requirements.

Width: Common widths range from 1000mm to 2000mm, which can be provided according to customer needs.

Length: Hot rolled stainless steel plates are usually provided in cut-to-length or coil form, and the length can be customized according to customer needs.

Production process

Hot rolling process: Hot rolled stainless steel plates reduce the hardness of the material and improve the plasticity and toughness by rolling the stainless steel billet at high temperature.

Surface treatment

Surface finish: The surface of hot rolled stainless steel plates is usually rough, which is suitable for subsequent processing.

Surface treatment: Different surface treatments can be provided according to requirements, such as pickling, polishing, etc.

Advantages

High Strength: The hot rolling process makes the stainless steel plate have higher strength and toughness, suitable for bearing greater pressure and load.

Good processability: Hot rolled stainless steel plates are easy to cut, weld and form, suitable for various manufacturing processes.

Corrosion resistance: Stainless steel material has excellent corrosion resistance and is suitable for use in harsh environments.

Application Areas

Construction industry: used for structural support, frames, curtain walls, etc.

Manufacturing Industry: For use in machinery, equipment, tools and other industrial applications.

Automotive industry: used in automotive chassis and body parts.

Chemical Industry: Used in equipment and pipelines, especially in corrosive environments.

Maintenance

Regular Inspection: It is recommended to regularly inspect the surface of the hot rolled stainless steel plate to ensure there is no oxidation and corrosion.

CLEAN: Keep the surface clean to avoid accumulation of dirt and chemicals.

Product Specifications

| Product Name | stainless steel plate |

| Type | Plate/Coil/Bar |

| Thickness | 0.03mm-300mm or as required |

| Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc |

| Material | 301, 304, 304L, 347, 316, 316L, 430, 410, 310, 310S, 0Cr13, 1Cr13, 3Cr13, 309, 904L, 253ma, 400, 440, 440C, 410, 316Ti, 420, 409, 409L, 317L, 321, 430F, 442, 416, 431, 420F, 201, 202 |

| Length | as required |

| Width | 3mm-2500mm or as required |

| Specification | Thickness: 2-14mm |

| Processing Method | Cutting, Bending, Stamping, Punching |

| Technique | Hot rolled / cold rolled |

| C | Si | Mn | Cr | Ni | S | P |

| ≤ 0.08 | ≤1.0 | ≤ 2.0 | 24.0~26.0 | 19.0~22.0 | ≤ 0.03 | ≤ 0.045 |

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥520 | ≥205 | ≥40 | ≤ 217HB;≤ 95HRB |

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/℃) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

| 9.01 | 200 | 14.4 | 13.8 | 94 |

Application

Can cut carbon steel, stainless steel, copper, aluminum and other pipes and profiles, such as: the tube, pipe, oval pipe, rectangular pipe, H-beam, I-beam, angle, channel, etc. The device is widely used in various kind of pipes profile processing field, shipbuilding industry, network structure, steel, marine engineering, oil pipelines and other industries.

transport

010203040506070809